The growing interconnectedness of smart devices—known as the “internet of things”—is changing the way the manufacturing industry operates and the products it produces, and UW-Platteville students have the opportunity to be at the forefront of this expanding field.

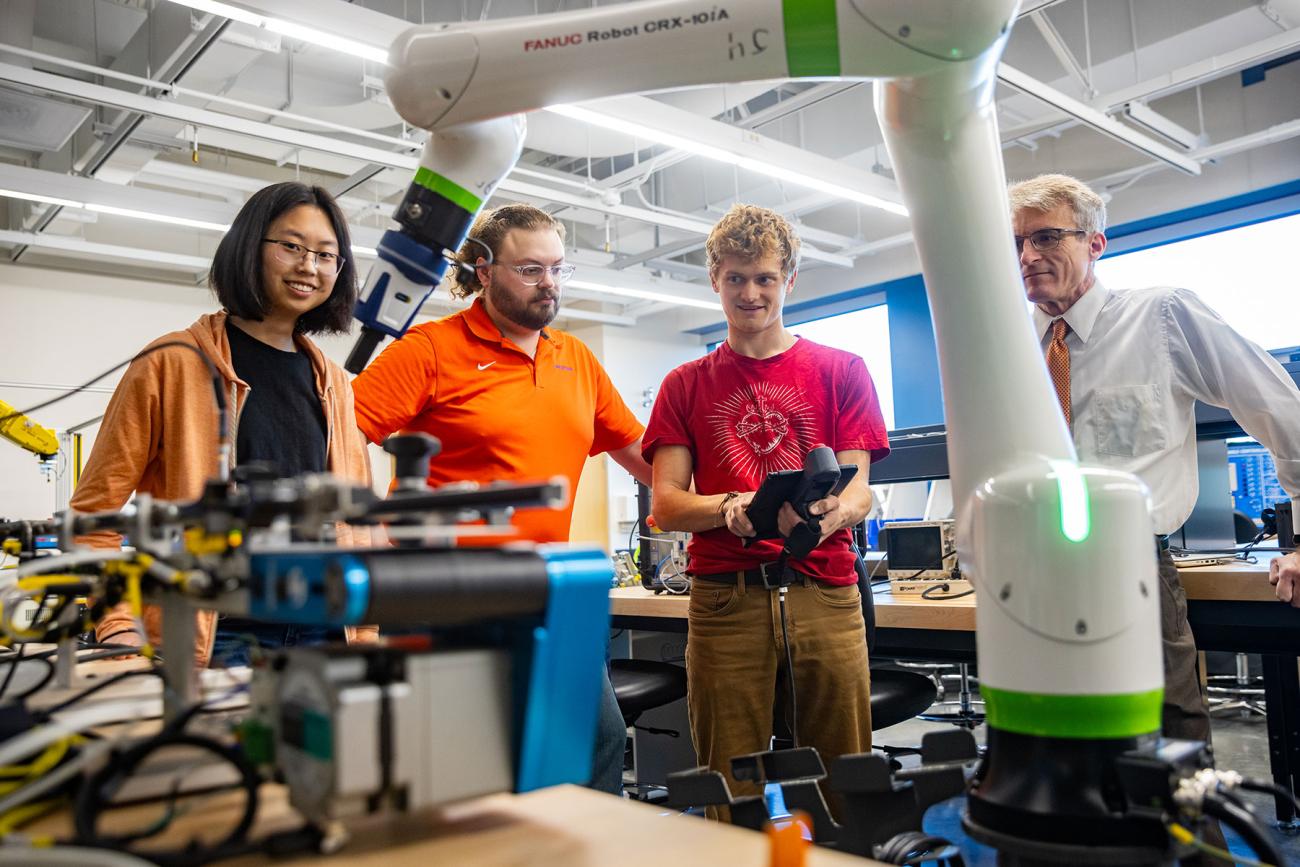

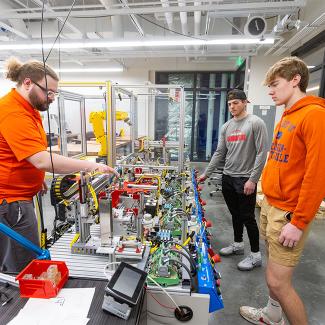

The Industrial Internet of Things (IIoT) Testbed, located in UW-Platteville’s new Sesquicentennial Hall, offers students a unique opportunity to gain hands-on experience using a small production line in this lab. Students learn about modern industrial controls and operation, PLC programming, networking, robot arm programming, and smart sensors. New equipment, including cloud servers for data analysis, is actively being added to the space.

Students using the lab will take away critical experience that gives them an edge when entering the workforce.

Equipment

See what makes UW-Platteville's lab unique

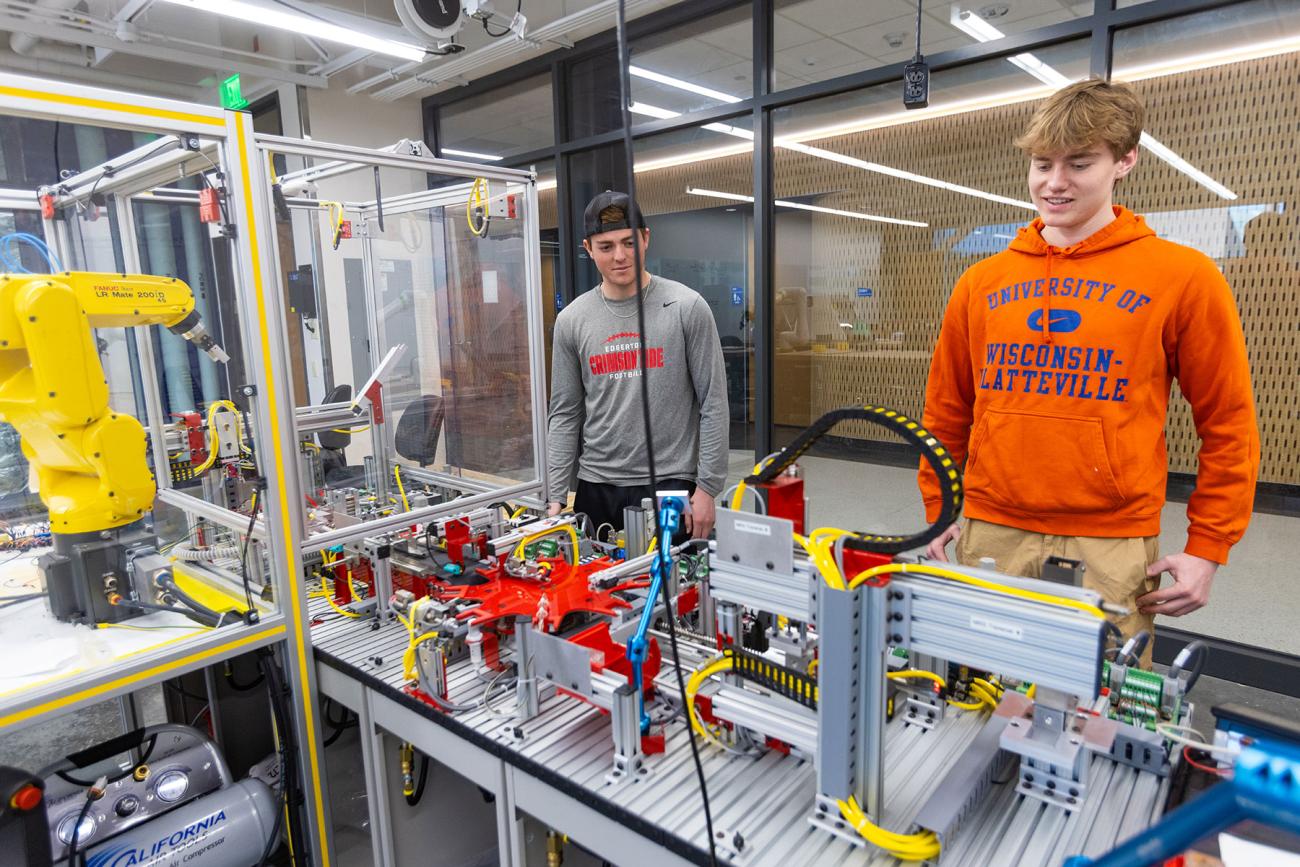

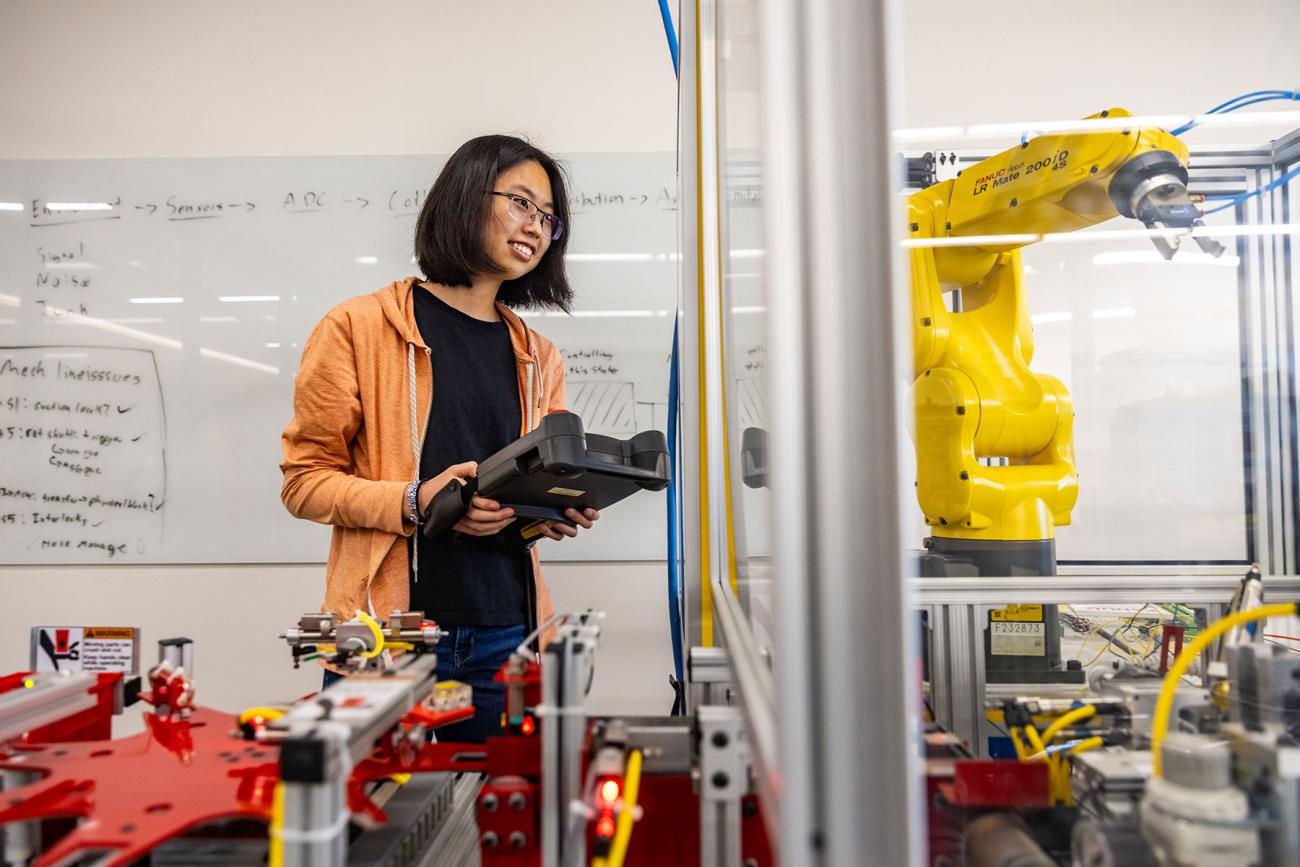

Automated assembly line

A modula assembly line equipped with a conveyor, multiple sensors, PLCs, and six-axis robot allows students to learn how to integrate equipment to automate an assembly process.

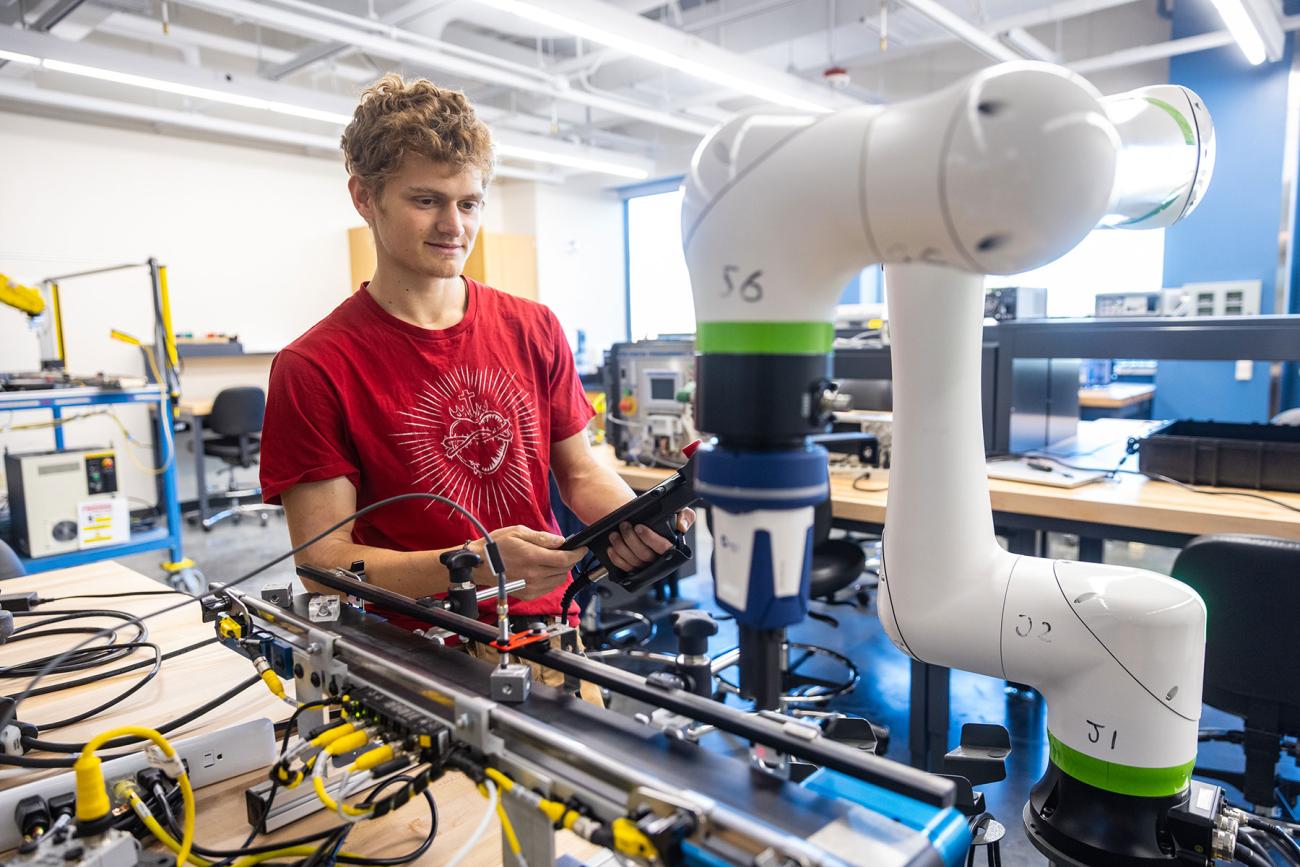

Cobot

Students can learn to program a collaborative robot (cobot) to complete a large number of tasks including assembly, vision inspection, and more!

Sensors and IIOT devices

The lab is stocked with sensors and a variety of IIOT devices to allow users to put together systems that are best for them and their own applications.

A closer look